What Working At The Jack Daniel Distillery Is Really Like

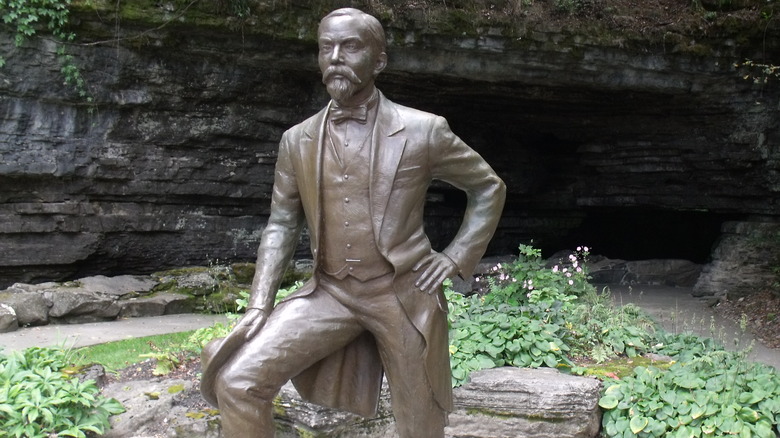

The Jack Daniel Distillery was founded in 1866 by Jasper "Jack" Newton Daniel and his first Master Distiller, Nathan "Nearest" Green in Lynchburg, Tennessee. Ever since then, the distillery has been successfully operating in the same location. In fact, today Jack Daniel's is one of the top-selling whiskeys in the world (via The Spirits Business).

As of 2021, the distillery spans about 3,000 acres (via Jack Daniel's Bottles). Much of this land is taken up by close to 100 barrel houses, where tens of thousands of barrels of whiskey are stored. Countless other buildings including the stillhouse where the whiskey is made are scattered across the property.

To keep this operation running smoothly, the Jack Daniel Distillery requires a lot of labor. The jobs range from behind the scenes to front and center in the tasting room. Keep reading to learn what it's like to work for one of the most beloved whiskey distillers in the U.S.

The atmosphere feels like one big family

The Jack Daniel Distillery has been a part of the Lynchburg, Tennessee, community for over 150 years. That means that generations of Lynchburg residents are bound to have worked for the company or know people who have. But is the relationship one of love or hate?

According to one former employee on Indeed, Jack Daniel Distillery was a "very great place to work" and it fostered a "very close family atmosphere." They went on to say that they "never had a dull moment," and the network of connections was long-lasting. Another former employee who worked in bottling agreed that the setting was "very family oriented." They continued, "They take care of you and are very fair with [their] employees." Meanwhile, a former server called their job both "fun" and "meaningful." They also said, "The company is always going out of [its] way to do what they can for their employees." Based on these accounts, it would seem that the distillery is a welcoming place to work.

There's still drama

However, as with any family, there is bound to be drama. Some people might become frustrated by managers who are too involved or conversely, too distant. What feels encouraging to one person may be viewed as meddling by another. There just isn't a one-size-fits-all approach when it comes to employment.

Case in point, a former barrel shop associate noted on Indeed that it was a "toxic workplace with the occasional drama burst." They had to deal with "narrow minded" and "intrusive coworkers and bosses." They further claimed that management treated their employees like "dirt on their shoe." Another former employee put it more diplomatically by saying that there was room for improvement when it came to "workplace drama."

A sales associate called their job "very stressful," and noted that in some departments it was tricky to get a promotion. Since they did not elaborate on why this was the case, one can only speculate. They also mentioned having to work all holidays and weekends, which is hardly conducive to spending time with one's actual family.

Workers receive free whiskey

Yes, you read that correctly. On the first Friday of every month — dubbed "Good Friday" by employees — each distillery worker is given a free bottle of whiskey. Master Taster Jeff Norman joked with Total Wine & More, "No one misses that day of work!" Usually, it's a bottle of Jack Daniel's Old No. 7, but the staff is sometimes treated to special edition items, such as rare products targeted for export.

Jack Daniel himself actually started this tradition as a way to show gratitude to his employees for all of their hard work. And as Inc. points out, free bottles are a terrific way to familiarize employees with the whiskey and get them "passionate about [the] products." They can share that bottle with friends and family, furthering the company's reach and perhaps winning over new customers in the process. Sounds like an all-around win.

It can be hard to get enough hours

Between housing costs, utility bills, transportation fees, healthcare, groceries, and more, just living your life can get expensive. It's important to have a reliable source of income to meet these needs but unfortunately, the Jack Daniel Distillery might not be it.

A former warehouse employee lamented on Indeed that while the job was fine, gaining a full-time position was difficult, and they couldn't collect enough hours. A temp employee echoed this sentiment, saying that while everyone was "very friendly and helpful," they needed full-time employment which was just too hard to achieve at Jack Daniel's.

A former assembler was also disappointed by the lack of hours since they were on call. An ex-production technician further explained that the "system works off a daily schedule," and "you might work one day one week [and] nothing the next week." This is hardly what one would call a stable income.

The production process remains traditional

The Jack Daniel Distillery has modernized many facets over the course of its 150-year history, but the basic distilling process remains the same as it was when Jack and Nearest first opened the distillery in 1866 (via Whisky.com). There are many myths about the origin of the name Old No. 7, but no one really knows with certainty. Whatever the story, it has grown to become one of the most prominent whiskeys in the world.

Jack's original recipe is comprised of 80% corn, 12% malted barley, and 8% rye, and it is still in use today. But that isn't the only aspect that makes Jack Daniel's whiskey unique; all of the water used in the distilling process comes from Cave Spring Hollow. Jack himself purchased the hollow and the land that surrounds it in order to take advantage of this naturally filtered pure spring water. The caves infuse some mineral content into the water while the limestone also eliminates iron, making for a better-tasting whiskey.

It's not all whiskey making

Jack Daniel's Tennessee Whiskey is currently owned by the Brown-Forman Corporation. Among the numerous job listings, there are positions to work for the Jack Daniel's brand all over the U.S. and across the globe! Yet even at the distillery in Lynchburg, Tennessee, there are a lot more jobs than just making whiskey; it's an all-encompassing operation.

Case in point, one key position is a warehouse barrel roller. This includes "filling barrels, dumping barrels, barrel selection, barrel repair, and sample collecting." (The barrels themselves have been crafted in Alabama at the Jack Daniel Cooperage since 2014.) Another important position is working along the bottling line. This job includes inspecting, corking, labeling, and packaging the filled bottles, all by hand.

Aside from the production, the distillery is also an attractive outing for tourists. Guided tours are offered to discover the distillery, which requires staff to lead the groups around the establishment and drive the shuttles (via Staffmark). And you can't forget the event coordinators and staff at the Jack Daniel Visitor Center and Homeplace.

You can't buy whiskey in a dry county, even when you helped make it

It's a good thing that Jack Daniel Distillery employees get a free bottle of whiskey every month because it is located in Moore County, which has been a dry county since Prohibition. As a result, no alcohol can actually be sold within county bounds, including at the distillery. Fortunately, drinking within a dry county in the privacy of your own home is just fine.

Visitors who take certain tours are given samples of various types of whiskey as well as a taste of the spirit at different points of the creation process (via the Sterling Traveler). Free samples can only be provided on the distillery's property. While you can't technically purchase whiskey from the distillery store, they have found a work-around. Customers may purchase "commemorative bottles" that are conveniently filled with whiskey. According to a review on TripAdvisor, certain special bottles may only be purchased on-site.

The road to Master Distiller is not easy

As of October of 2020, Jack Daniel's eighth Master Distiller is Chris Fletcher. His chemistry education and experience set him up for the job, including some time working for Brown-Forman in research & development. But that isn't the only tie Fletcher has to the distillery. He actually grew up in Lynchburg, and his grandfather, Frank Bobo, was Master Distiller from 1966 to 1989.

In March of 2021, Lexie Phillips was promoted to Assistant Distiller, becoming the first woman to hold the title in the company's history. Prior to obtaining her role, Fletcher held the position. Phillips also has family ties to Jack Daniel's and holds a degree in agricultural science from Middle Tennessee State University.

This isn't to say that a college degree is required to become a Master Distiller. As Moonshine University points out, there is no single path to achieving this designation, and it's ultimately up to the requirements of each individual distillery. According to Distiller, "experience and education" typically determine where you fit in when seeking employment at a distillery. And like Fletcher and Phillips, you will have to work your way up which can take many years.

Only full time employees get benefits

A good benefits package can make or break what is otherwise a terrific job. As a former Jack Daniel Distillery employee reported on Indeed, their benefits included health insurance, two weeks of paid time off, holiday pay, and a 401k. Similarly, a current worker declared that the "benefits and compensation package are very fair," and if it weren't for other reasons they would stay until retirement.

Unfortunately, that would seem to only apply to full-time company employees. A part-time server who gave their position the highest ratings possible and raved about how much they loved their job said the only downside was the lack of "certain benefits." As well, a part-time bottling department employee shared on Indeed that sick leave is only an option for full-timers because temporary employees risk being written up. It would seem that even full-time temps are not offered benefits. At least there's still that free bottle of whiskey.

Jack Daniel's strives for sustainability

In 2018, USA Today reported that Jack Daniel's "exceeded their limits for chlorine and other pollutants that can harm aquatic wildlife." The company rectified the problems, but as the demand for whiskey increases, waste water remains a concern. Given that all of the water used to make the whiskey comes from the same spring, water conservation is a priority (via Jack Daniel's).

To answer growing concerns about sustainability, Jack Daniel's has implemented a number of zero-waste initiatives. The sugar maple charcoal used in the filtration process is reused as "smoking pellets for barbecues." Shrink wrap left over from shipping is made into decking material. The grain and yeast used in the distilling process are given to cows for feed. The wood from the barrels is reused in various ways, and paperwork has gone digital.

To ensure that wood for barrels and charcoal will always be available, the distillery participates in the DendriFund's White Oak Initiative "to assess and preserve woodland conditions," and the University of Tennessee's Tree Improvement Program "to research and study white oak and sugar maple trees."

You may have to deal with some funky smells

Making whiskey is an involved process incorporating many processes. According to Saucey, the main steps are malting, mashing, fermentation, distillation, maturation, and then bottling. Amidst these stages, many important changes occur, each with their own unique odors.

Moonshiner and brewer John Wheeler says that mash (which at Jack Daniel's is 80% corn, 12% malted barley, and 8% rye) has an aroma that is "pungent, yeasty, and harsh in nature." During fermentation, the yeast produces an array of smells, including "the scent of rotting eggs or sulphur." Worse smells can occur throughout the entire process, indicating that something has gone awry and needs to be corrected.

The distillation process has its own collection of odors (via Difford's Guide). As the alcohol is boiled off in the still, different chemicals give off aromas. While many of them are almost fruity, others are less pleasant and chemical in nature like acetone.

And, of course, whiskey has its own smell! According to Whisqiy.com, Tennessee whiskey smells similar to bourbon, but with "smoky and sooty smells" from the charcoal used in the mellowing process.

The distillery can be a pretty loud working environment

The Jack Daniel Distillery is a fully-operating factory that follows whiskey production from grain to bottling and shipping. This complex process requires a lot of big machinery, which means certain parts of the distillery are going to be pretty noisy!

Amanda Macias went on a distillery tour and shared the experience on Insider: "I was a little worried going into the still house because the machinery was really loud. The room was deafening and super hot." She also noted the smell of the sour mash was "intense and made [her] eyes water." It sounds like a pretty overwhelming environment to face on a daily basis. Another distillery tourist noted on TripAdvisor that their guide spoke loudly, adding, "which is a good thing."

Distilleries don't always make good neighbors either as certain noises can be so loud and continuous that life can be unbearable for those who live close by (via Andover Advertiser). Thankfully the Jack Daniel Distillery sits on thousands of acres of its own property.