What To Know Before Taking Another Sip Of Maker's Mark

Chances are if you enjoy hard alcohol, you've gone through a bourbon phase. And you wouldn't be alone. The brown liquor grew so much in popularity over the past couple of decades that in 2019, distilleries in Kentucky (where 95% of the liquor is produced) manufactured over 1.7 million barrels of bourbon — almost four times greater than the amount distilled in 1999, per VinePair.

Bourbon, which is whiskey that is distilled with at least 51% corn and aged in new charred oak barrels, is known for a sweet taste that differentiates it from other forms similar spirits like rye whiskey or Scotch. One of most acclaimed bourbon brands is Maker's Mark. In fact, it was the fourth best-selling American whiskey brand worldwide in 2020, behind mainstays Jim Beam, Jack Daniel's, and Evan Williams (via The Spirits Business).

Easy to drink, priced well, and widely available, Maker's is a great jumping off point to dive into the world of bourbon. Whether you enjoy it neat, on the rocks, or shaken into a classic cocktail like a Manhattan or Old Fashioned, here is what you need to know about Maker's Mark.

Maker's Mark was released at a luxury price when bourbon was in decline

Cocktail aficionados in this day and age are accustomed to seeing a fancy bourbon-based drink on most bar menus, but that wasn't always the case. According to Serious Eats, bourbon was hard to come by during the early-20th century thanks to Prohibition and World War II. By the time the spirit was more widely available in the 1950s, it had garnered a blue collar reputation, and many liquor lovers stuck their noses up at the beverage.

Enter William "Bill" Samuels Sr. — the founder of Maker's Mark. He not only had the crazy idea to re-imagine bourbon as a craft spirit, but also to sell his product at the then luxury price of $7. This was a gamble in 1957, considering there was not a market for high-end bourbon at the time. But it wasn't until the 1980s that the Samuels family's risk really started to pay off. This was when Samuels Sr. convinced airlines to offer Maker's Mark on flights, and The Wall Street Journal ran a front page story on the brand: "Maker's Mark Goes Against the Grain to Make Its Mark" (via Serious Eats). This proved to be a gamechanger for the brand. "The article was huge for us; it created consumer interest outside Kentucky and gave the brand credibility," Bill Samuels Jr., who succeeded his father as the head of Maker's Mark, told Whiskey Magazine.

The former CEO started out as a rocket scientist

While the Samuels family has been in the whiskey business for generations, Bill Samuels Sr.'s son — Bill Samuels Jr. — didn't immediately join the family trade. Despite growing up in Kentucky bourbon country as the godson of liquor legend Jim Beam, Samuels Jr.'s early career actually took him way out of his world. In college, he decided to study engineering and eventually landed a job working on the Gemini and Polaris rockets, TheStreet explains.

Samuels Jr. ultimately left his unique career as a literal rocket scientist in the early 1970s to follow his equally unique family tradition of distilling craft whiskey. But returning to his roots had its own pressures. When Samuels Jr. ultimately took over as president of Maker's Mark in 1975, his father gave him some sage advice: "Just don't screw up the whiskey" (via VinePair).

Did he succeed? The proof, as they say, is in the barrels. During Samuels Jr.'s tenure as president and CEO, the company greatly expanded its production. According to a 2013 Time article, Maker's Mark sold merely 250 cases of bourbon in 1959; in 2013, it sold 1 million. The magazine attributes Samuels Jr.'s success to his strategy of building brand awareness "bar by bar." While Samuels Jr. has since left the responsibility to not mess up the family recipe with his son, Rob Samuels, he's still involved with the company as Maker's Mark Chairman Emeritus (via American Distilling Institute).

Maker's Mark once tried to change the proof of its signature bourbon

Maker's Mark made smart choices in developing brand recognition over the past decades, but in 2013 the company also almost made one that would've derailed its reputation. With bourbon booming across the United States, Maker's Mark faced what many would consider a lucky problem: The demand for its whiskey had grown exponentially. But while other bourbon brands might've called on third-party manufacturers to produce more barrels, Maker's Mark prides itself on only being produced in one location — at its own distillery in Loretto, Kentucky (via WFPL).

The company needed to decided how to meet its new demand, and made a judgment call to slightly reduce the proof of its namesake bourbon (from 45% to 42%). The response was an immediate uproar from fans. Maker's Mark's leadership insisted they had conducted numerous taste tests and noticed no difference between the versions. But according to Time, bartenders across the country — the same ones who Samuels Jr. had spent his career winning over — were now threatening to ditch the product. They said a lesser proof would dilute the bourbon and not offer the same quality spirit as before.

Ultimately, Maker's Mark's devotees won out and the company announced it would not tweak the bourbon's recipe. Instead, the company opted to spend $67 million to expand its distillery operations and accommodate the increased demand (via U.S. News & World Report).

The distillery is a National Historic Landmark

Maker's Mark's headquarters, located 45 minutes south of Louisville, isn't just noteworthy for being home to all of the company's bourbon production. The distillery is also listed on the National Register of Historic Places and was designated a National Historic Landmark in 1980.

According to the Kentucky Historical Society, the site has a storied history of producing spirits that predates the Samuels, beginning as a gristmill distillery operated by the Burks family in the early 1800s. The property stayed in the family for four generations, all of whom are rumored to have had something to do with the whiskey trade. This included forming Burks Spring Distilling Co. in 1905.

In 1953, Bill Samuels Sr. purchased the property to house Maker's Mark. His wife, Margie Samuels, took a particular interest in the history of the distillery. Per the Maker's Mark website, Margie is credited by some as being the inventor of whiskey tourism. She convinced her husband to put as much money into restoring the distillery and its grounds as he did for bourbon manufacturing. Margie envisioned the space as being a draw for visitors for more than just its whiskey production. It is thanks to her devotion that thousands of tourists visit the distillery's red trimmed buildings — and taste some great bourbon while they're at it — every year (via Imbibe).

Maker's Mark is on the Kentucky Bourbon Trail

If you love all things bourbon, why not make a trip out of it? The Kentucky Bourbon Trail (KBT) offers whiskey fans an opportunity to explore 41 different bourbon-producing distilleries across the state. The trail was created in 1999 to celebrate the spirit which is synonymous with Kentucky.

The company's headquarters offers more than just a chance to admire the previously mentioned historic buildings on site; you can actually become part of the bourbon production process. Visitors to Maker's Mark have the opportunity to hand-dip their own bottles in the company's signature red wax. (A word to the wise: If you want to take a tour of Maker's Mark, make sure to reserve in advance. It costs $20 for adults and no ticket sales are available on site.) Foodies will also find something to enjoy at Maker's Mark's headquarters. The location includes Star Hill Provisions, a restaurant featuring small plates and fancy cocktails (featuring bourbon, of course). Most of the restaurant's dishes feature ingredients grown on the on-site farm, and the menu changes seasonally.

If you need a place to lodge, considering staying at the Maker's Mark family home. Rooms at the Samuels House are available to rent with prices starting at $850 per night.

The founder's wife came up with Maker's Mark's signature look

Maker's Mark's fans can also thank Margie Samuels for the bourbon's name as well as some other signature branding features. According to the Maker's Mark website, Margie owned a large collection of 19th century cognac bottles, which typically are sealed with red wax. While her husband was perfecting his bourbon recipe, Margie also was playing around in the kitchen. She melted red wax in the same fryer which typically was used to cook fried chicken and developed Maker's Mark's signature seal.

Another of Margie's collections inspired Maker's Mark's name, the company notes. She owned a number of fine pewter pieces, and metalworkers would include a signature of sorts — a "maker's mark" — on their best work. In addition to inspiring the company's name, the concept of a "mark of the maker" became part of the bourbon packaging itself. Margie designed an insignia that can be found on Maker's Mark's bottles to this day. It includes a star (to represent Star Hill Farm, where the family lived), an "S" (for Samuels), and the Roman Numerals IV (to symbolize the multigenerational distilling history in the family).

Margie's numerous contributions to the Maker's Mark brand earned her a spot in the Kentucky Bourbon Hall of Fame in 2014. She was the first woman inducted based on her work on behalf of a distillery.

Maker's Mark's founder destroyed his family recipe

You'd imagine that a sixth-generation whiskey distiller would likely have some respect for the family recipe. But in the case of Maker's Mark, this couldn't be further from the truth. While on a mission to produce a more upscale bourbon, Bill Samuels Sr. set the sole copy of his family's 170-year-old recipe on fire — literally (via Maker's Mark website).

The Samuels family began making bourbon in the late 1700s. Robert Samuels started things off by distilling whiskey for his family and friends, and his grandson opened the family's first commercial operation in the mid 1800's, Whiskey Magazine reports. According to Red Head Barrels, only breaks in bourbon production were during Prohibition and for a few years between distilleries in the 1940s.

But if it's broke — fix it. And Samuels Sr. believed that the family's original bourbon was generally too bitter, so he set out to craft something entirely different. To speed up the trial-and-error process, he tried out flavor profiles by baking loaves of bread with different grain combinations (via Maker's Mark). He eventually ended up swapping out the bitter rye typically used in bourbon with a red winter wheat. With this change, Samuels Sr. created the sweeter taste associated with Maker's Mark and won over a new generation of bourbon drinkers.

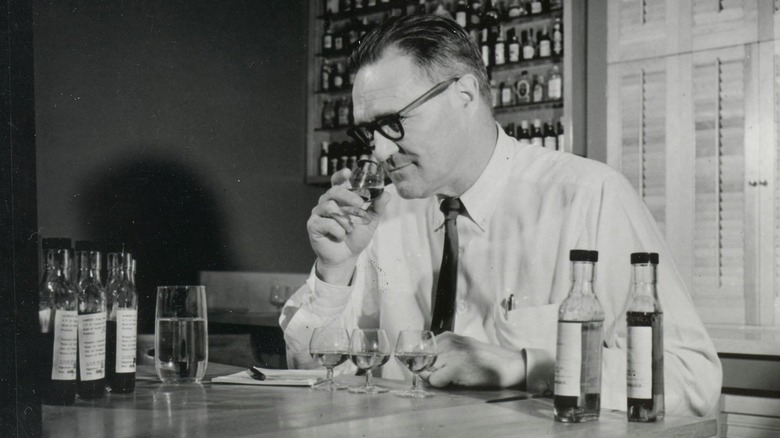

Maker's Mark rotates its barrels by hand for optimum temperature exposure

At a time when many beverage companies have automated parts of their operations for efficiency, Maker's Mark is still committed to craft. And sometimes craft takes a while to get right. Per the Maker's Mark website, an old joke at the distillery is, "If we could make it any faster, we wouldn't." One time-consuming part of the distilling process for Maker's Mark is it still rotates its whiskey barrels by hand to ensure optimum temperature exposure. Other aspects of the company's aging process are equally as old-fashioned. For example, the Master Distiller and an expert tasting panel use taste as opposed to a set amount of years to determine when a barrel has finished aging, The Whisky Shop reports.

Bourbon barrels aren't considered ready until they've spent a minimum of three sweltering Kentucky summers at the top of the rack house. Through this process, the whiskey gains color and flavor as it expands through the wood. According to the Maker's Mark website, batches typically take six to seven years to be aged to perfection.

Almost every ingredient in Maker's Mark bourbon is produced locally

Maker's Mark is only distilled at its own location in Kentucky, but the company's commitment to keeping things local goes beyond the bourbon production itself. Most of the components of the whiskey also are grown nearby. According to the Maker's Mark website, the company partners with a local farm to source the red winter wheat that is so crucial to the bourbon's flavor profile. However, wheat only makes up 16% of the "mash" — or the mixture that is initially distilled to create the whiskey (via The Whisky Shop). Seventy percent of the blend is corn, which also is grown on a local farm. (Barley rounds out the remainder of the recipe.)

High-quality local water also plays a crucial role at Maker's Mark, which is the only distillery that has its own water source and watershed, according to the Maker's Mark website. The region's groundwater has a limestone aquifer that acts as a sort of natural filter, producing water rich in calcium and magnesium that is ideal for fermenting yeast — and it makes for great drinking water, too. Speaking of yeast, the company uses an over 150-year-old heirloom strain to produce every bottle of bourbon.

"Would it have been easier to switch to cheaper stock yeast when everyone else was? Sure," the company notes on its website. "But, it wouldn't be better. And, it wouldn't be Maker's Mark."

Maker's Mark is owned by a Japanese company

For all of its commitment to keeping bourbon production within Kentucky, Maker's Mark isn't technically owned by anyone in the Bluegrass State — or anyone in the United States in general. The company is still "steered" by the Samuels family, but is actually a part of Beam Suntory Inc., which is a subsidiary of Suntory Holdings of Osaka, Japan, TheStreet reports. Other well-known Beam Suntory whiskey brands include Jim Beam, Knob Creek, and Basil Hayden's; it also owns a number of cognac, tequila, and vodka brands.

When Suntory Holdings acquired Beam back in 2014, consumers were told that nothing would change with their beloved spirits (via NBC News). And so far, that promise appears to have been kept. Suntory Holdings certainly knows a thing or two about whiskey, after all. The company's beverage empire includes the Yamazaki brand, which is produced in the oldest commercial distillery in Japan.

The company uses its fans as informal salespeople

If you count yourself among Maker's Mark's biggest fans, the company has a job for you. You can join its team of Maker's Mark Ambassadors, an informal group of bourbon lovers who are so committed to the brand that they promote it in their spare time. Joining the Ambassador program comes with a number of unique perks sure to entice a whiskey lover. In addition to receiving insider news and invitations to exclusive events, Ambassadors are assigned bourbon barrels with their names on it — literally. Each Ambassador receives a barrel with their name engraved on an attached placard. Once the barrel has finished aging, they also can purchase one-of-a-kind bottles with their names printed on the label (via Maker's Mark website).

Is it worth it? The jury's out on that. One Redditor who claims to have received the Ambassador kit remarked that they had no idea what to do with the many included business cards. But others said the program was an opportunity to feel like a part of the Maker's distilling experience — and possibly grow a budding romance. "I got my bottle a few years ago with mine and my wife's name on it," one user chimed in. "We both signed up when we were only dating and had our names on the same barrel. We married before our barrel was ready."

Maker's Mark didn't release a new product for over half a century

For its first 50-plus years in business, Maker's Mark only produced one product: its namesake bourbon (via The San Diego Union-Tribune). The year before Bill Samuels Jr. retired as CEO and president of the Maker's Mark, he helped launch Maker's Mark 46, the first new product since the company's founding. The well-received variety became the "swan song" of his storied career, as Drink Spirits tells it.

Maker's Mark 46 differs from the company's flagship bourbon because it is aged for eight to 12 months longer in barrels containing French oak staves. A few years after the successful launch of Maker's Mark 46, the company added another new product: Maker's Mark Cask Strength. The offering is bourbon that comes straight from the cask without additional proofing (via Maker's Mark website). It was bartenders who tasted bourbon out of the cask when visiting the distillery that really drove the product launch, Maker's Mark Master Distiller Greg Davis told Drink Spirits.

Maker's Mark also started a Private Selection program, which allows retail partners to choose stave types to finish out the aging process; over 1000 combinations are possible, the company explains.

Maker's Mark is a leader in sustainability

You might not look to bourbon distillers as leaders in fighting climate change, but Maker's Mark is certainly making waves in the area. In January 2022, the company announced that it became the largest distillery in the world to earn B Corporation (B Corp) certification — meaning it meets environmental and social sustainability standards. One way the company is reducing its environmental footprint is through its zero waste to landfill program. All the waste at the distillery will be either recycled or repurposed in some way, down to Maker's Mark bottles, which are pulverized into sand for use in hiking trails across the property.

The distillery also has taken great strides to preserve the important water source it relies on for its bourbon production. It created a 33-acre natural water sanctuary that protects the water by protecting the forest around it. The trees are essential to purifying, regenerating and replenishing the water supply by acting as a sort of natural filter.

Maker's Mark even looked at the sustainability of the source of its bourbon barrels: white oak trees. To make sure they were around for future generations of distillers, the company opened a research repository for the trees that serves as a "living laboratory" for scientists (via Maker's Mark website).