This Is The Most Expensive Soy Sauce & How It's Made

Soy sauce has anchored East Asian cuisine for thousands of years. Even Louis XIV's chefs are said to have called it "black gold" for its ability to transform dishes. The power of this salty brown condiment lies in its distinctive umami flavor – the seductive savory taste found in certain aged foods such as miso, aged cheese, and some types of mushrooms.

Japanese soy sauce, known as shoyu, can be purchased at just about any grocery store for a few dollars, but as with most aged foods and beverages, prices skyrocket based on the method and duration of preparation. The basic process for making shoyu starts with steamed soybeans and wheat. These are combined with Aspergillus oryzae or sojae mold to kickstart fermentation. Saltwater is added, and the mixture is then left to age for at least a few days before being pressed to expel the delicious brown liquid you find lining grocery store shelves.

This brewing process is labor-intensive and varies greatly between manufacturers. Large-scale producers use acid-hydrolyzed vegetable protein to skip the lengthy fermentation process and provide large quantities of affordable soy sauce in a fraction of the time. On the other end of the spectrum, small, artisanal breweries allow their products to ferment for years before selling them for a premium. At the farthest end is Kamebishi, a producer that ferments some of its soy sauce for 38 years and sells it for hundreds of dollars.

The Kamebishi brewery is steeped in history

As you might expect for a brewery that ages its products for decades, Kamebishi has been around for centuries. It has been owned by the same family for 17 generations, and the current owner, Kaori Okada, maintains its more than 200-year history by continuing to use traditional methods of brewing. The company is still based in the same building that Okada's samurai ancestors inhabited, a red farmhouse situated in Higashikagawa, a town on Japan's smallest major island, Shikoku. The site has been recognized by the Japanese government as a National Tangible Cultural Property due to its storied history and tourists flock to the brewery to observe its manufacturing process. The name comes from "kame," meaning turtle, and "hishi," meaning diamond. Both are auspicious symbols in Japanese lore and have been associated with the company since its inception in 1753.

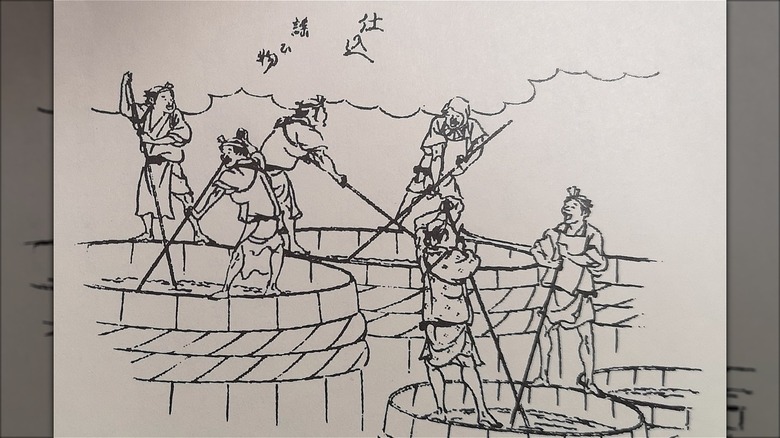

One of the traditions that Kamebishi continues to use in their brewing process is the 250-year-old mushiro koji method, which involves laying the inoculated grains on bamboo trays to ferment. This takes longer and requires more observation than the standard mechanized process used by many breweries but produces a greater depth of flavor. The mushiro koji method has itself been designated by the Japanese authorities as an Intangible Folk Cultural Property, and Kamebishi is the only brewery still using it.

It's a small operation

In addition to remaining a family-run company, Kamebishi does not operate on a mass scale like other soy sauce producers. Due to the traditional mushiro method and the length of aging, it generates fewer products and has a smaller reach, but its relatively small footprint is an effective part of the brand. The official website is only in Japanese, and purchasing bottles of soy sauce from outside the country must be done through a third party.

The company has found other ways to fortify its business since Okada took over in 2001. One of its main supplementary sources of income is tours. If you visit the seaside town of Higashikagawa (which has a population of just about 28,000), you can visit Kamebishi's headquarters. There, you can buy soy sauces, soy salt, chocolate, and even ice cream and pizza made with their signature umami products. For an additional cost, you can even stay on-site in a special residence built over a century ago.

The process begins with soybeans

Like all shoyu, the production process starts with soybeans. Kamebishi uses whole soybeans sourced from Japan. Large-scale breweries, in contrast, often use dried soybeans that have had their oil removed. As any cooking aficionado knows, fat is one of the best ways to bring out flavor in cooking, and by retaining it in their soybeans, Kamebishi heightens the flavor of its final products.

The brewers soak the beans overnight and then steam them in a large machine that is kept at a constant temperature to ensure all the beans are softened evenly. The process takes about 18 hours and is a crucial foundation for successful fermentation.

The wheat, most of which is cultivated locally in the same prefecture as the company's headquarters, is roasted at nearly 400 degrees Fahrenheit and then ground into powder. Many soy sauce producers use crushed wheat because it is faster to produce than powder, but Kamebishi takes additional time to grind it into a substance resembling wholegrain flour. This ensures that the wheat coats each soybean instead of providing incomplete coverage. Once the powdered wheat and steamed soybeans are combined, they are inoculated with mold spores.

Kamebishi's koji is the secret to its success

Koji, often hailed as the unsung hero of Japanese cooking, is the name given to grains that have been inoculated by the mold, Aspergillus oryzae. This miraculous fungus is believed by historians to have been used in Asian cooking for more than 9,000 years, and it underpins some of the most iconic products of Japanese cuisine. It provides the foundation for sake (which uses rice as a base rather than soybeans or wheat), miso, and mirin (which is also primarily rice-based).

While the majority of manufacturers embrace the efficiency of using machines to mix koji, Kamebishi takes a more nuanced approach, breaking it down into multiple steps. Compared to the days of fermentation and years of aging that go into every batch of Kamebishi soy sauce, making the koji is quick, and the attention to detail that adds extra time here and there makes all the difference.

First, the brewers mix the koji mold powder with the powdered wheat by hand. Then, the soybeans are hand-tossed with the mixture until they are evenly coated. This ensures that the koji mold is seamlessly incorporated and in the best position to work its magic. At this stage, the koji is ready to undergo the ancient mushiro method which is one of Kamebishi's greatest claims to fame.

It uses the traditional mushiro koji method

Soy sauce manufacturers can conduct the fermentation process in multiple ways. Most large-scale manufacturers choose to use machines, but Kamebishi uses the mushiro method, which involves spreading the koji on straw mats that sit on bamboo trays. During fermentation, the mold produces enzymes that break down the starches in the soybeans and wheat into sugar and the protein into amino acids.

The mushiro process takes three days and three nights, during which workers stand guard over the trays, checking the temperature every hour to make sure the koji is warm enough to spur fermentation but not warm enough to kill the fungus. Kamebishi alters the temperature of the room through the traditional process of opening and closing the windows rather than using an artificial climate control system. Eventually, fermentation causes the soybeans to swell and create their own heat. Towards the end of the three days, the koji can be close to 90 degrees Fahrenheit without an external heat source, but the brewers maintain a strict temperature between 82 and 86 degrees Fahrenheit.

This painstaking fermentation method produces a flavor that can't be matched by machine-orchestrated means, but it is not a practical option for manufacturers planning to sell their products on a large scale. Kamebishi uses a two-story room and stacks the trays of koji as many as 14 layers deep, but even at its capacity of 180 layers, the brewery can only produce half of what other producers make through a mechanical process.

The koji is turned into moromi

The next step is to add liquid. The koji, now thick and crumbly, is combined with salt water to create moromi, a substance that looks like unappetizing tan-hued sludge but is actually the precious foundation of the coveted condiment. Just as the soybeans and wheat are carefully procured, so too is the salt. Kamebishi uses a combination of sun-dried Australian salt and Japanese sea salts. This mixture ensures a precise mineral balance, providing the nuanced flavor the brewers are seeking. The salt not only brings out the desired taste but also serves as a natural preservative, repelling harmful bacteria and preventing toxic mold from flourishing.

As the mash ages, the enzymes from the mold continue to break down the grains' starches into simpler sugars and the proteins into amino acids. At the same time, other microorganisms contribute to the fermentation, producing alcohol and lactic acid.

Kamebishi exceeds the standard multi-month aging period many times over, but it isn't just the length of time that makes the difference. The company also uses special vessels for aging the moromi that have a time-honored history.

The mixture is aged in cedar barrels

Vintners and distillers often boast about the containers they use to age their products. Oak barrels are known for the alluring flavors of vanilla, spices, and caramel they impart to red wines and bourbon, while the Italian brandy known as grappa is traditionally aged in cherry, oak, or acacia casks to provide a golden color and woody flavor. The vessels that foods and beverages are aged in have a profound impact on how they taste, especially when the aging process is a matter of years, not months.

Most soy sauce brewers, including the ubiquitous red-capped Kikkoman, age their moromi in stainless steel tanks. With this setup, the mash breaks down into amino acids and alcohols to provide the tanginess and umami that we associate with shoyu, but it gains no outside flavor.

Kamebishi enhances this process by aging its moromi in cedar vats. Unlike the oak casks used for aging bourbon, however, these vessels are not mainly used for their woody flavor. Cedar is relatively flimsy and porous compared to hardwoods, which allows bacteria to flourish. Kamebishi's cedar vats are hundreds of years old and are stored in a loft where the airflow and temperature can be controlled. Fungi, hundreds of years in the making, grow on every surface. The brewery estimates that there are at least 230 varieties and, far from being a health hazard, these beneficial molds produce more alcohols to intensify fermentation and deepen the flavor.

Some of the sauces are aged for decades

Kamebishi ages its soy sauce for a minimum of a year and a half, and the prices rise in direct correspondence to the aging period. A 900-milliliter bottle of sauce that has been aged for two years, for example, only costs about $40 from some retailers, while a 55-milliliter bottle that has been aged for 20 years can cost about $120. That pales in comparison to the more than $300 price tag for 38-year-old bottles. In a few decades, the brewery will begin selling soy sauce that has been aged for 50 years.

Many manufacturers have turned to chemical methods to produce shoyu, opting to skip the fermentation process altogether and bottle their products within days. However, even large brands that still use the natural brewing method age their products for a fraction of the time that Kamebishi does. For example, Kikkoman, one of the most recognized soy sauce brands in the world, ferments its products for only a few months.

Soy sauce connoisseurs are willing to pay a premium for well-aged products because longer fermentation brings out naturally occurring yeasts and alcohols that create a host of new flavors. Salt, umami, sweetness, bitterness, and sourness all create a complex balance that is far removed from the simple salty umami taste of many soy sauces on the market.

Extracting the shoyu can take longer than a month

Once the moromi has fermented in the cedar vats for the prescribed number of years, the brewers extract the soy sauce. The method of extraction varies depending on the aging period. Moromi aged fewer than 10 years is a thick, dark brown liquid that can be spread on squares of cloth that are stacked on top of each other and pressed with a heavy machine. The pressure squeezes out liquid that is collected and heated to a temperature high enough to stop fermentation. Heat also pasteurizes the contents, enhances the flavor, and deepens its color. It is then ready to bottle and sell. Kamebishi can extract 800 liters of soy sauce per day with this method.

Older moromi, however, is much harder to extract. More than a decade of aging turns it into a dry, black crust that does not produce liquid when squeezed. Instead, Kamebishi drills a hole into a PVC pipe, covers it with gauze, and puts the end of the pipe into an empty jar inside the moromi. Slowly, moisture accumulates on the gauze and begins to drip into the jar. It can take upwards of a month to fill a single bottle with the liquid, further extending a decades-long process.

Kamebishi's brewing process is a dying art

Soy sauce can be found all over the world, but many of the products you find at the grocery store are a far cry from the condiment you would have found hundreds of years ago and which Kamebishi continues to lovingly produce. Only 1% of Japanese soy sauces are aged in wooden vats (via Umami Info), and Kamebishi is the only brewer still using the mushiro koji method. The labor-intensive process is impractical for large-scale operations and is reflected in the hefty price tag, but faster, cheaper methods do not produce comparable results.

To make more affordable products, many soy sauce manufacturers bypass fermentation by breaking down the soybeans and wheat with hydrochloric acid. They then improve the lackluster results with ingredients such as brown food coloring, sugar, preservatives, and flavor enhancers. This allows consumers to have an approximation of the coveted condiment for a few dollars, but these products offer none of the explosion of flavors produced by the traditional, years-long fermentation process that Kamebishi follows. Like adding a few tablespoons of Smirnoff to grape juice and calling it wine, this type of soy sauce hardly compares to the real deal.

Kamebishi soy sauce is cheap compared to similarly made products

Sinking triple digits into a small bottle of soy sauce might seem exorbitant, but compared to the hundreds and even thousands of dollars that some consumers spend on balsamic vinegar and wine, it's a modest sum. Balsamic vinegar can cost anywhere from a few dollars to a cool $1,000 if you're tempted by a bottle that has been aged for 100 years. Wine can also cost as little as a handful of dollars to hundreds of thousands of dollars if you're hankering for a 1995 Domaine de la Romanée-Conti Grand Cru or an 1869 Château Lafite-Rotschild.

In this light, a measly $300 doesn't seem like that much, especially considering the many similarities between the production of these prized items. Premium soy sauce, balsamic vinegar, and wine are all made using simple ingredients, whether it's the soybeans, wheat, and saltwater of traditionally made soy sauce or the grape must (whole grapes including stems and seeds) in balsamic vinegar or the grapes that make wine. All are naturally fermented and aged. The quality and origins of the raw materials influence the price, though the concept of terroir is reserved for grapes. Scarcity and the length and hands-on nature of the aging process also play key roles in the price. Despite these similarities, soy sauce is not treated as a collectors' item in the way that wines and some balsamic vinegars are, which may partly explain its relative affordability.