Here's The True Difference Between Processed Cheese And Real Cheese

We may receive a commission on purchases made from links.

Cheese has been a much-appreciated staple in cuisines around the world for thousands of years. Whether it's sprinkled on pizza, melted in a sandwich, or enjoyed in pasta, cheese brings a unique flavor and texture to our meals. Usually made from cow, goat, sheep, or buffalo milk, cheese is also a common accompaniment to wine and cured meats.

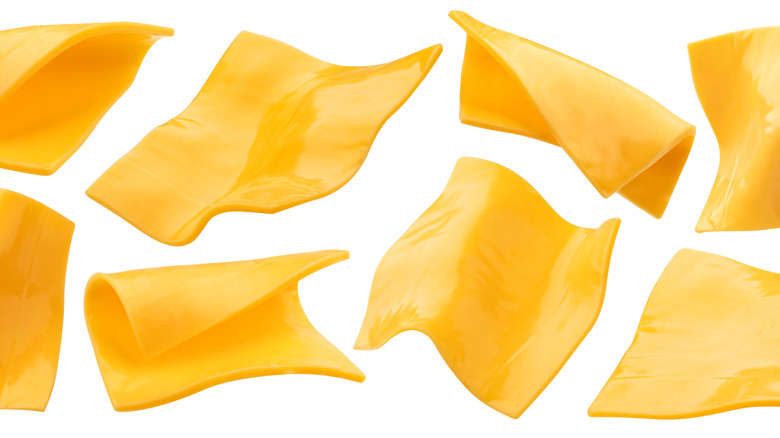

While natural cheese and processed cheese are used interchangeably in some dishes, their differences are as stark as chalk and... cheese. Real cheese carries traditional craftsmanship and remarkable diversity in taste and processing methods. From the crumbly quality and sharp flavor of an aged parmigiano reggiano to the velvety smoothness of gorgonzola, each cheese type reflects its origins and the expertise of its cheesemakers. In contrast, processed — or American cheese — is usually mass-produced to ensure consistent flavor and texture. It's also commonly sold in a variety of pre-packaged forms such as slices, spreads, and even sprays. So what exactly sets processed cheese and real cheese apart? Keep reading to find out!

Processed cheese is a relatively recent invention

The art of cheesemaking can be traced back over 4000 years, as evidenced by tomb murals discovered in Egypt. Although the exact origin of cheese is unclear, it's believed to have been stumbled upon thanks to the practice of storing milk in bags made from animal stomachs. More specifically, it's theorized that the presence of natural rennet in the lining of the animal stomach pouches led to the separation of the milk into solid curds and liquid or whey. By 100 BC, cheesemaking flourished throughout Europe and the Middle East.

But the history of processed cheese couldn't be more different. Despite sometimes being called American cheese, processed cheese wasn't developed in the U.S. The invention of processed cheese has its origins in the early 20th century when the dairy product emerged as a response to the need for a more convenient and long-lasting cheese product. In 1911, the first commercially-manufactured processed cheese — made with emmentaler and sodium citrate — was invented in Switzerland by Fritz Stettler and Walter Gerber. The main motivation behind the innovation was extending the product's shelf life so it wouldn't spoil during shipping. Five years later, Kraft patented the first American processed cheese. The popularity of Kraft's version of processed cheese grew rapidly. By 1917, it found its way onto grocery store shelves and became a component of the U.S. Army rations during World War I.

Processed cheese is made with more ingredients

Real cheese contains four essential ingredients: milk, starter culture, salt, and rennet — an enzyme that helps coagulate the milk. Other ingredients — such as starches, pulses, and hydrocolloids — are sometimes utilized in the cheesemaking process to create different cheese types.

Processed cheese is an entirely different beast. Although it contains different types of cheese blended together, some hesitate to put processed cheese and real cheese in the same category. There's a good reason for this — processed cheese only contains around 50% cheese. As per the FDA's standards, dairy products must consist of at least 51% natural cheese to be officially recognized as cheese. There are a lot of non-cheese ingredients in processed cheese that give the product its distinct flavor and texture — including mysteriously-sounding ingredients like calcium phosphate, sodium citrate, sodium phosphate, and sorbic acid. Imitation cheese also contains preservatives — such as potassium sorbate and nisin — to prolong its shelf-life.

Real cheese and processed cheese are made using different production methods

Often, the process of making natural cheese is a lengthy one. Natural cheese production starts with combining milk and rennet, which causes the milk to separate into curds and whey. The curds are then cut and drained to expel even more moisture. The curds are then cooked, salted, pressed, and left to age for varying durations of time.

Depending on the type of cheese, the aging process can take several years. In an interesting incident from 2012, a cheese shop owner made an intriguing discovery at the back of their store — 40-year-old blocks of cheddar! The cheddar ended up being some of the oldest cheese made available for sale to the general public. Ken McNulty, the president of Wisconsin Cheese Mart, shared his experience after tasting the cheese with TODAY, saying, "It's the sharpest cheese I've ever tasted. Although what you'd expect is that it would be really dry, but it's actually very creamy."

Processed cheese undergoes a more industrialized manufacturing process. First, real shredded cheeses become mixed and subjected to melting temperatures between 158 and 203 degrees Fahrenheit to liquify the fats. Subsequently, a combination of other ingredients — including emulsifying agents, coloring, stabilizers, preservatives, and additional salt — joins the mixture. Finally, the resulting blend cools and cheesemakers shape it into various forms to fit the desired final product.

Real cheese comes in more varieties and flavors

The variety of flavors found in natural cheeses surpasses the range available in processed cheeses. These flavors differ based on ingredients, moisture content, and aging duration. Supposedly, France boasts over 1,000 types of cheeses. There are fresh cheeses like creamy and mild mozzarella and tangy cheeses like feta. Hard cheeses offer robust options like grana padano.

Processed cheeses often contain additives to imbue them with additional flavor. This is convenient and cost-effective for manufacturers because it reduces the amount of real cheese required in the production process. To impart additional flavors, processed cheeses are often made with substances like enzyme-modified cheese, wood smoke, and starter distillate. Moreover, a variety of spices, along with preparations made from meat, fruit, and vegetables, are sometimes added to the recipe to add character to the finished product.

Due to these additives, processed cheese tends to be blander and more uniform-tasting than real cheese. When Vox spoke with several cheese experts to see how they feel about processed cheese, their opinions were divided. Some expressed a nostalgic fondness for the products. However, others like American Grilled Cheese Kitchen's Heidi Gibson shared a more critical perspective, saying, "I don't like American cheese — I've always thought it was kind of gross, and I won't serve food I'm not proud of... It's too plasticky and chemical-y."

Processed cheese and real cheese have different textures and melting points

According to WebstaurantStore, there are six types of natural cheese — including fresh cheeses, soft cheeses, semi-soft cheeses, semi-firm cheeses, hard cheeses, and blue-veined cheeses. Not only do these cheeses vary in consistency, but they also possess different melting points. Typically, cheeses that contain a significant amount of moisture melt easily at lower temperatures of around 86 Fahrenheit. However, cheeses that are less moist like a sharp cheddar require higher temperatures of approximately 160 Fahrenheit to melt.

In the U.S., the Code of Federal Regulations (CFR) distinguishes between five different processed cheese products, including pasteurized processed cheese, pasteurized blended cheese, pasteurized processed cheese foods, pasteurized processed cheese spread, and pasteurized cheese spread. While these products may differ in their composition — including fat, moisture, and pH level — they essentially all exhibit a mild flavor and silky texture.

Depending on their intended applications in cooking, processed cheeses can be tailored to have distinct melting points. But it's worth noting that imitation cheeses typically contain high levels of liquid, resulting in lower melting points. Perhaps the owner of Untamed Sandwiches and Untamed Taqueria, Andy Jacobi, sums up the distinction between the melting properties of real and processed cheese best, saying, "[Real cheese] might take a few seconds longer on the griddle to melt, but that's because real cheese has texture and inconsistencies that make it taste so complex, which American cheese doesn't have (via Vox)."

Real cheese is better for you

Since real cheese is made from natural ingredients, it's a relatively healthy food — provided that it's eaten in moderation. More specifically, real cheese offers a range of nutritional benefits, including nutrients such as calcium, niacin, phosphorus, high-quality protein, and vitamins A and B12.

While processed cheese contains minerals such as iron, calcium, copper, and potassium, it's also packed with nasties such as high levels of sodium and trans fats. High amounts of sodium have been linked to blood pressure, which increases an individual's risk of heart disease and stroke (via MedicineNet). Meanwhile, trans fats can have been known to elevate LDL, or bad cholesterol, levels, leading to clogged arteries and an increased risk of heart problems (via MedlinePlus).

Depending on the brand, substitute cheese can contain artificial flavors, colors, preservatives, emulsifiers, and stabilizers. Still, it's not all bad news. If you're looking to lose weight, light versions of processed cheese can be a better option than real cheese since they often contain less fat than regular cheese.

Processed cheese comes as a spray

American cheese is available in various forms, ranging from blocks and individually packaged slices to cheese sprays. The first cheese spray that entered the market in 1966 was called "Snack Mate." Following the merger of its original manufacturer, Nabisco, with Kraft in 1983, the processed cheese was rebranded as "Easy Cheese." Today, the product comes in a variety of flavors, such as cheddar, sharp cheddar, American, and cheddar and bacon.

If you've never tried a spray-on cheese spread, you might be surprised to know that the product comes out of the can in a string-like form. In the case of "Easy Cheese," the can is designed with a propellant at the bottom to ensure that it doesn't mix with the food. This feature means that the product doesn't require refrigeration and can be dispensed even when the can is upside down.

Typically, processed cheese sprays contain a laundry list of ingredients such as cheddar cheese powder, margarine, herbs, lactic acid, sodium phosphate, and artificial flavorings. If you think most of these compounds don't sound overly healthy, you're correct. As reported by CN Shining, a study conducted by the University of California found that nine out of the 12 cheese sprays that were tested contained phthalates, which can cause hormonal problems and cancer. They also discovered traces of lead and cadmium, which can lead to neurological damage.

Real cheese and processed cheese have different culinary applications

Due to their specific characteristics, natural cheese and processed cheese serve distinct culinary purposes. Real cheese possesses complex flavors, textures, and nuances that enhance a range of dishes and makes it a preferred choice for melting or grating. Natural cheese is commonly used at upscale restaurants in dishes like lasagna, quiches, and casseroles.

While processed cheese lacks the depth of flavor of real cheese, it offers other benefits such as convenience and flavor consistency. The smooth texture and uniform melting properties of imitation cheese make it ideal for topping burgers and sandwiches or adding creaminess to sauces. Many of us will probably agree that American cheese is a delightful addition to mac and cheese. This is because, unlike some real cheeses, processed cheese doesn't separate or turn to oil during the melting process. Chef and owner of Randall's Barbecue, Jared Male, praises processed cheese in an interview with Vox, stating, "I find it adds an extra level of gooeyness. I can't see American cheese ever really being phased out, and I don't know what could realistically replace it." His perspective highlights the unique qualities that processed cheese brings to certain dishes, emphasizing its ability to enhance texture and provide a satisfying melt.

Processed cheese has a longer storage and shelf life

While the shelf life of different types of natural cheeses varies, real cheese doesn't keep as well as its processed counterpart. Moisture content plays a significant role in determining spoilage rates for natural cheeses. Softer cheeses deteriorate more rapidly once taken out of their packaging (we are talking about cheeses that come in oxygen-free plastic packaging here). HealthLine suggests that soft cheeses like brie or feta last in the refrigerator for up to seven days, while hard cheeses like cheddar and parmesan retain their freshness for approximately one month.

Since processed cheese contains preservatives and has high salt content, it generally lasts longer than natural cheese. In fact, certain imitation cheeses don't require refrigeration. As per HealthLine, American cheese can be safely stored in the refrigerator for up to two months. This longer shelf life, in addition to its consistent flavor, often makes processed cheese an appealing choice for fast food chains and other food establishments that prioritize convenience and long-lasting ingredients.

Real cheese is more expensive

It's no secret that processed cheese is significantly cheaper than real cheese. As we all know, real cheese can be pricey. In 2021, The Cheesemaker provided estimates for the prices of various cheese types. Mozzarella was priced between $3.36 and $6.68 per pound, cheddar ranged from $3.36 to $9.07 per pound, and Swiss and Gruyere cheese between $3.44 and $9.31 per pound. In contrast, the same platform reported that the cost of processed cheese ranged between $1.97 and $5.98 per pound.

Why is there such a huge price difference between these cheeses? Processed cheese is relatively easy and fast to produce. Processed cheese's production method allows companies to create a uniform and consistent product that is easy to produce on a large scale. They also don't need to age their cheese, significantly cutting down on overall production costs. Furthermore, the ability to store processed cheese for longer periods results in significant cost savings, which are then passed on to consumers.