The Future Is Now: Robots Can Make Fried Chicken

Innovation has never been so "finger lickin' good." For South Korean fried chicken restaurant Robert Chicken, having robots run the kitchen was once a dream that was finally achieved in 2018. It might be hard to imagine this kind of technological advancement becoming widespread in the food and beverage industry. However, according to Meticulous Research, food robotics are projected to have an annual growth rate of 11.6% from 2021 to 2028. Investors are continuously supporting a more tech-friendly world, slowly extending their robotic arms into various sectors as the world moves into the future.

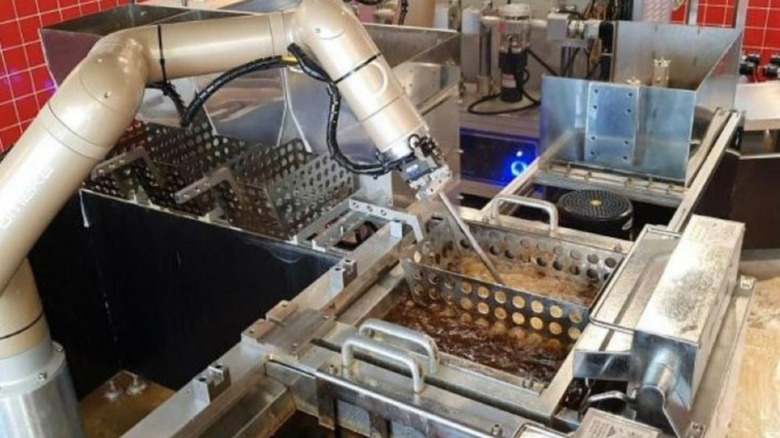

Robert Chicken made itself a home for robots with the help of food tech startup Robo Arete, founded by CEO Kang Jiyoung. "I thought the day would come where a robot fries chicken and a drone delivers it. But there was no such startup in South Korea, so I started the business," she shared with Korea Economic Daily Global. A single robotic arms staffs Robert Chicken and is programmed to prepare perfectly crispy, high-quality fried chicken every time — 50 baskets per hour, to be exact. On its website, Robo Arete lists the benefits of using automated technology for this purpose, which may be pretty inspiring for industry players. (KFC, you hearing this?)

Per Eater, Robert Chicken is opening a location in New York City's Koreatown, its first outside of Seoul. Though this will be a new concept for New Yorkers, the chain has been at its robotic frying game for about five years.

Increasing efficiency while decreasing workplace injury

In an interview with Korea JoogAng Daily, Kang shed light on her goals for her robot arms, powered by cloud-based technology. "I don't think there's any point in doing a food business with robots if it can't boost productivity," the CEO said, explaining that flashiness isn't the point. "I want them to be fast, precise in their job, with zero fluctuations in food quality." She also mentioned how grueling it is to be a fry cook, operating oil that reaches temperatures of 338 degrees Fahrenheit in a fast-paced environment. It's a pretty dangerous job, especially if the cooks need to maintain a level of speed and consistency. Using the robotic arm eliminates these safety risks.

You can see the robot in action in a YouTube video from Korea JoogAng Daily, which details the entire process of the "one-man franchise" that Robert Chicken has become due to this breakthrough technology. Once an order is placed by the customer, a (human) employee places it on a conveyor belt to be layered with flour and heaped into a basket. The robot takes it from there, dunking and shaking the basket in oil just like a human fry cook would to achieve peak crispiness. Then the fried chicken is sauced up and boxed by human hands. The most lucrative part for Kang, most likely, is that the robot can "man" three friers at once.